Micro EDM

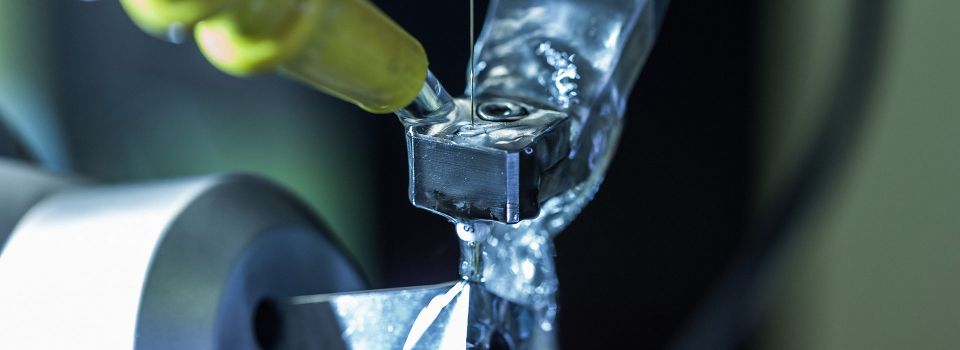

Micro EDM – manufacturing of miniature components

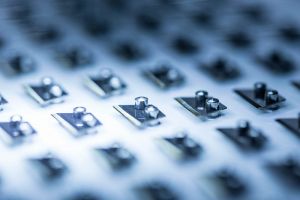

One of the most innovative trends in manufacturing is the miniaturisation of components. Micro components are often needed in small to medium lot sizes, since they often differ greatly in terms of requirements and applications.

Our high-precision Micro EDM systems enable the EDM manufacturing of extremely small individual parts. Slots of 50 μm in width can be cut to a tolerance of less than 5 μm by using wire diameters as fine as 30 μm. On our 5-axis Micro Drill EDM machine we use electrodes with diameters down to 0.05 mm. A built-in dressing unit also permits the manufacturing of electrodes with a diameter of 0.01 mm, which can be used to drill micro holes of 0.020 mm or less.

Applications:

- Micromechanics

- Micro-moulding dies

- Micro-nozzles and spinnerets

- Micro-optics and electronics

- Micromedicine

Important technical data:

- Extremely fine surface quality with Ra = 0.08 μm

- Extremely small wire diameter: 0.02 mm to 0,2 mm

- Micro holes from 0,05 mm

Machinery:

- 6x GF Machining Solutions Cut 1000

- 2x Sarix Sx100

- 1x Sarix Sx200

Workpiece:

- Length x width up to 300 x 200 mm

- Height up to 80 mm

- Weight up to 35 kg

Workspace:

- Maximum travel distances: x, y, z 220 x 160 x 95 mm

Contact us - We will be glad to advise you: +49 (0)6192 9945 0 or vertrieb@cfk-online.de