Additive Manufacturing – Selective Laser melting

Selective Laser Melting (SLM) – 3D printing using light and metal powder

CFK's comprehensive expertise in additive manufacturing based on Selective Laser Melting, developed by CEO Dr.-Ing. Christoph Over and others at the Fraunhofer Institute, can look back on 15 years of experience in applications. These years of experience guarantee top quality in consulting and manufacturing.

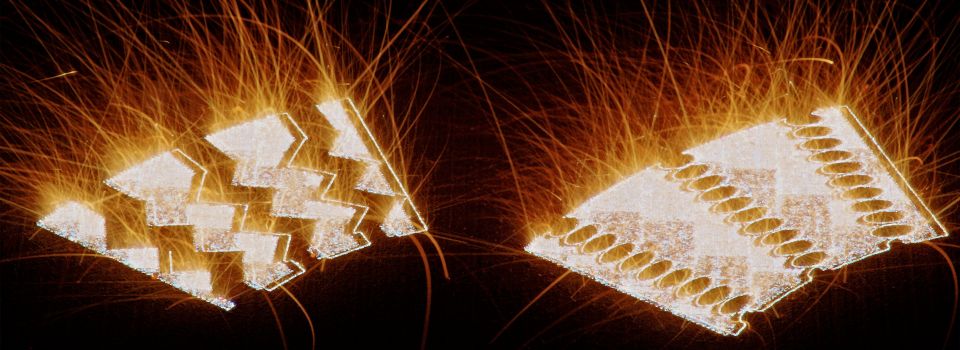

Selective Laser Melting is an additive manufacturing process that creates complex three-dimensional components layer-by-layer from a powder material using laser. It is particularly used in functional prototypes, small series of complex components or assemblies, tool inserts and medical implants.

In Selective Laser Melting, components are generated directly from the 3D CAD data. A layer of powder is applied to a build platform. Then a laser melts the areas of the layer that will later be present as solid material. The build platform is then lowered and the process repeats until the component is complete. The resulting build of the metallic parts can achieve densities of >99,5% and are just as tough and hard as conventionally manufactured materials. The parts can even be further machined with conventional processes without any problems. Series-production materials are used, such as different types of steel, titanium, aluminium alloys as well as nickel and copper alloys.

Selective Laser Melting offers incredible options for the design and production of components

Selective Laser Melting permits the manufacturing of complete components that cannot be manufactured using conventional methods, such as milling or casting. This provides geometric and design options that have never been possible before. For example, contour-adapted channels within components or load-appropriate internal structures are possible.

Since the components are manufactured in a single process step, entirely new possibilities are opened up for manufacturing components in one piece instead of joining them from different individual parts.

What we offer: In addition to additive manufacturing of components from various series materials, we can also offer you a custom analysis of the economic and technological advantages of Selective Laser Melting and advise you on the design and layout of your components in accordance with your specific needs.

Machinery:

- 1x SLM 280 2.0 TWIN with 2x 700 W laser

- 1x SLM 280 2.0 TWIN with 2x 400 W laser

- 1x Concept Laser M2 cusing Multilaser with 2x 400 W laser

- 1x MYSINT 100 with 200 W lasers

Our Materials:

- Titanium TiAl6V4

- Titanium CP-Ti

- Aluminium AlSi10Mg

- Stainless steel 1.4404

- Tool steel L-40 (Formetrix Inc.)

- Tool steel 1.2709

Other materials on request

In our download area, you can find all the data sheets of additive manufacturing process using Selective Laser Melting.

Contact us - We will be glad to advise you: +49 (0)6192 9945 0 or vertrieb@cfk-online.de