Die Sinking

Die Sinking on track-controlled 5-axis machines

Through overlapping movements in all axes, Die Sinking enables the generation of a variety of shapes, which in some cases are impossible to achieve with any other processing system.

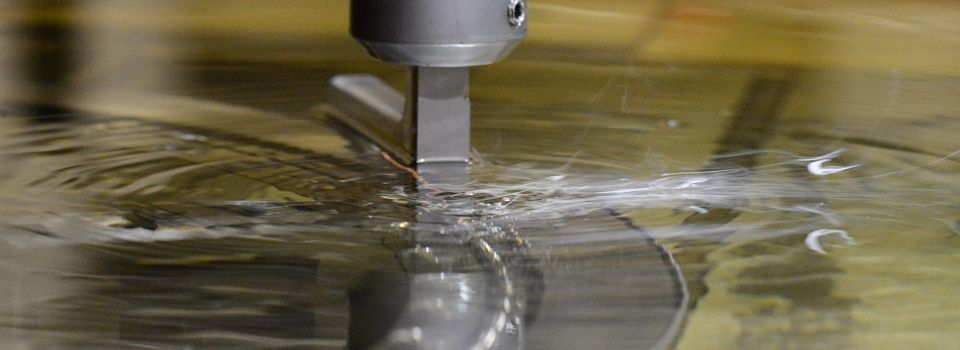

Copper, tungsten copper and graphite are used as the electrode materials in Die Sinking on our five-axis Die Sinking machines. The workpiece is created through spark formation, from the electrode to the workpiece resulting in a negative shape. It is located in a dielectric bath (oil of various viscosities, depending on the application) which is ionised by the discharge.

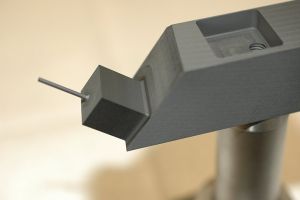

The movable machine head carries out movements along the Z axis and rotation in the C axis, while the table executes movements along the X and Y axes. These movements and an optionally applied rotational axis make the process ideal for all possible shape contours and for the processing of hard-to- machine materials.

Machinery:

- 2x GF Machining Solutions Form 400

- 1x GF Machining Solutions Form 3000

- 1x Agie Spirit 4

- 1x Agie Spirit 2

Workpiece:

- Length x width up to 2000 x 1200 mm

- Height up to 800 mm

- Weight up to 3000 kg

Workspace:

- Maximum travel distance x/y/z: 1200 x 600 x 800 mm

- C axis that can be continuously controlled over 360°

Contact us - We will be glad to advise you: +49 (0)6192 9945 0 or vertrieb@cfk-online.de